What is a load cell and how does it work?

A load cell is an electro-mechanical sensor used to measure force or weight. It has a simple yet effective design which relies upon the well-known transference between an applied force, material deformation and the flow of electricity. They are incredibly versatile devices that offer accurate and robust performance across a diverse range of applications. It’s no surprise that they have become essential to many industrial and commercial processes, from automating car manufacturing to weighing your shopping at the checkout. As technology explodes forward, many new and exciting applications are emerging that also stand to benefit from using load cells. New advances in robotics, haptics and medical prostheses, to name a few, all need effective ways to measure forces and weights. New types of load cells are continuously being designed to meet the needs of this ever-changing market.

How load cells work

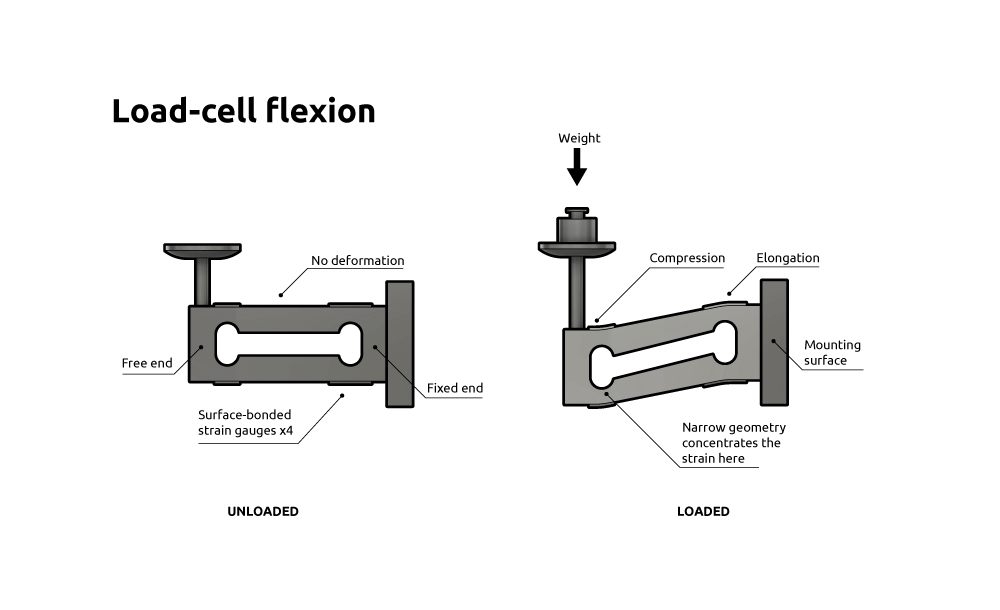

When we use load cells, one end is usually secured to a frame or base, while the other end is free to attach the weight or weight-bearing element.

When force is applied to the body of the load cell, it flexes slightly under the strain. This is similar to what happens to a fishing rod when a fisherman hooks a fish.

The fisherman will secure the rod in their hands while the fish applies a pulling force on the other end of the fishing line. The result of this force is that the fishing rod bends, with a bigger, stronger fish, causing the bend to be more extreme.

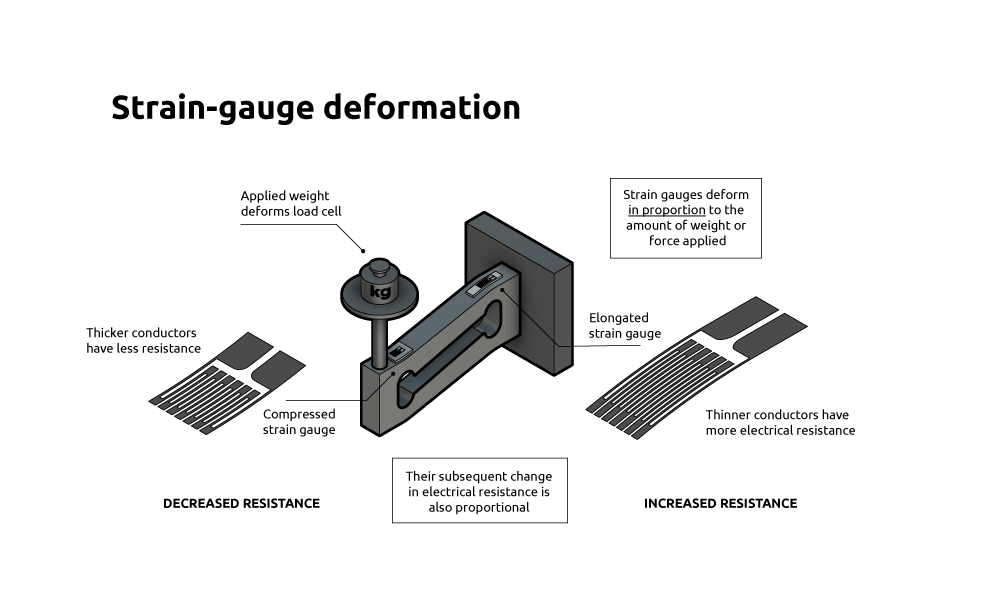

When this action happens to a load sensor, the deformation is very subtle and not visible to the naked eye. To measure the deformation, strain gages are tightly bonded to the body of the load cell at pre-determined points, causing them to deform in unison with the body. The resulting movement alters the electrical resistance of the strain gages in proportion to the amount of deformation caused by the applied load.

Using signal conditioning electronics, the electrical resistance of the strain gages can be measured with the resulting signal being output as a weight or force reading.

Technology of a load cell

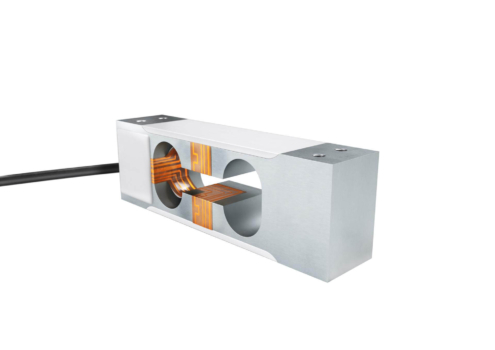

A typical load cell consists of two parts: the main body and an attached electrical circuit. The main body is what bears the weight or force and accounts for most of the load cell’s size. Typically, it is made from high-grade steel or aluminium, which ensures mechanical reliability, and predictable and uniform strain distribution.

The electrical circuit is housed within the load cell, tightly bonded to the main body. The circuit includes strain-gauges which are specialised parts of the circuit designed to sense the deformations of the main body.

These strain-gauges consist of thin, electrically conductive wire or foil arranged in a tight zig-zag pattern. This pattern makes them sensitive to stretch and compression along their length, but insensitive across their width. As such, they can be precisely positioned to sense forces that run along particular axes. For example, shear beam load cells have their strain gauges positioned at a 45-degree angle to the loading axis, so as to maximise the detection of the shear strain running through the load cell.

-

Environmental Protection

Depending on the setting, a load cell can find itself in very different environmental conditions. Naturally, a clean room within a medical laboratory differs greatly from the underbelly of an open-cast mining truck, yet both may use different load cell types. It is therefore important that they are adequately protected from the outside environment, to ensure their lasting performance for their intended use.

Most load cells will be potted. This means that the cavities are filled with an epoxy or resin material which fully covers the electronic components. This helps to protect the circuits from outside damage and humidity and also helps to dissipate heat.

Some load cells feature hermetic seals for the most complete environmental protection. A fully welded seal provides an airtight and robust enclosure, standing up to the most challenging environments.

ATEX and FM certificates are available for some load cells. These certificates indicate that it is appropriate to use in potentially explosive environments without the risk of sparks. This is ideal for activities that release flammable gases or vapours such as vehicle paint spraying or workplaces that handle fine organic dusts such as grain flour or wood.

-

Load Cell Accuracy

Different tasks require different degrees of accuracy. A medical scale that measures drug doses obviously needs to have greater resolution than an industrial scale that weighs large amounts of gravel or sand. As such, you will find different types of load cell that offer varying levels of accuracy and capacity, to accommodate these diverse applications.

International rules and agreements exist that aim to provide some quality-control over weighing and force measuring equipment. The idea is that such regulation will help promote harmony among different jurisdictions, facilitating trade and economic activity.

Internationally, the International Organization of Legal Metrology (OIML) governs these metrological regulations, and in the USA the National Type Evaluation (NTEP) Committee does the same.

Many commercial activities where product is sold by weight require legal-for-trade weighing equipment. This is equipment that has been certified by the relevant authorities (OIML, NTEP or national standards) for use in such applications. Typically, for commercial weighing scales, you will see them certified to a C3 class under OIML.

Load cells with OIML or NTEP certification will be suitable for legal-for-trade applications. Sometimes they will have both OIML and NTEP certification, others might have only one, depending on the market or region being sold to.

Outside of these certifications, load cells are labelled general purpose (GP). These are not certified but can often offer similar levels of accuracy. This is ideal in situations where legal-for-trade regulations do not apply.

-

Installation and use

The performance of a load cell depends on many factors. Central among these is proper installation and alignment. It’s often said that a load cell is only as good as its mounting. As such, it is important to follow the manufacturer’s recommendations carefully in order to get the best results from your device and to ensure safe and long-lasting use. These recommendations often include information on proper mounting and alignment of your load cell, appropriate fixing and fastener choice, the use of accessory mounting hardware, electronic adjuncts and calibration procedures.

Working closely with your load cell supplier, you ensure that you choose the best strategy and product to suit your particular needs and through continued support, trust that your solution will be effective and long-lasting.

Types of loadcell

A load cell is available in various shapes and configurations that can be specified for use in different application areas. Commonly, load cells fall into four different category areas, however, their core technology remains the same.

The main category of load cell are:

Beam

Beam

load cells are highly versatile sensors that typically work as cantilevers with

one end being fixed and the other end free to deflect when subjected to a

force.

Some beam load cells may also be considered double-ended, meaning the sensor is fixed at both ends and loaded in the centre.

Single Point

Typically, load cells rely upon the applied force being placed at a central point of the sensor body. Deviation of the centrally applied force will result in a loss of accuracy.

Single point load cells work differently, allowing for off-centre loading whilst maintaining accuracy. This ability makes them an ideal choice for applications where load is applied with a degree of placement variability.

Compression

As the name suggests, a compression load cell measures a squashing or pushing force. Generally their design mimics a column, giving the sensor additional strength for use in high capacity, static applications.

Tension

A tension load cell is primarily used to measure a pulling force, whereby the load is suspended from the foot of the sensor, causing it to stretch.

Tension load cells are sometimes called S-type or S cells due to their shape resembling the letter S. Many tension load cells can also be used to measure a compressive force, making them highly versatile.