What is a compression load cell and how does it work?

A compression load cell is one of the major categories or types of load cell commonly found within the weighing industry. Other types include, for example; tension, beam and single-point. Compression load cells, as their name suggests, measure pushing or squashing forces, and are typically installed underneath what is to be measured or weighed. Unlike tension load cells, these are unidirectional, only designed to measure the downward compression. (Tension load cells also tend to be capable of measuring compression too).

The actual internal workings of a compression load cell can be quite varied. They can be based on shear, bending, ring-torsion or column measurements. Although the uses can be quite diverse, one of the main applications for these kinds of load cells is in very high capacity static weighing, such as silos and vehicle scales.

Working principle

Compression load cells, like all other modern load cells, are essentially transducers that convert force or weight into an electrical signal. They do this with strain gauges attached to the body of the load cell. When under compressive load, the body of the load cell deforms slightly. This is detected by the strain gauges which deform in unison with the body, resulting in a change of voltage. This voltage signal is proportional to the initial force or weight and can thus be used to calculate it.

Design

A classic example of a compression load cell is the column or canister -style load cell. These are typically cylindrical-shaped devices with a mounting surface at the top and bottom ends. Inside there is a central core or column that functions as the weight-bearing element. Strain gauges are bonded to the surface of this column, orientated in such a way as to detect the deformations that occur under load. Usually, the load cell is encased in an outer sheath for protection and isolation of the internal elements from the environment. Many are hermetically sealed for use in harsh or dangerous environments.

These load cells are robust and accurate solutions, suited to applications that involve high-capacity static weighing. It is vital that the cells are properly aligned during installation, to ensure accurate readings. Typically this is achieved by coupling them with specially designed mounting hardware.

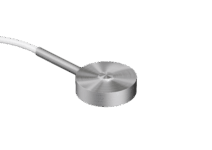

Other common designs for compression load cells include button load cells, which are compact and low profile, and often used within test and measurement applications. Additionally, thru-hole or doughnut load cells feature a central aperture so that the apparatus can be passed through. An example of such an application is in a pump monitoring system within the oil and gas industry.

Flintec Products

Flintec has several different compression load cells for purchase, accommodating both large and small volume orders. All our products are entirely manufactured by us, ensuring high-quality materials and excellent build quality. Should you need something unique, we can help you with a custom solution. As part of our service offering, our capabilities include mechanical design, electrical and software development, testing and calibration, regulatory and certification governance, as well as fully project managed projects.

Flintec compression load cells